Efficiency, accuracy, and dependability are critical in today’s industrial and construction settings. In order to ensure that buildings and infrastructure projects are finished properly and on schedule, the equipment employed in their construction, support, and maintenance is essential. Solutions for structural equipment are made to satisfy the rising need for quicker, safer, and more sophisticated building techniques. These solutions provide essential tools and equipment that support increased worker safety, productivity, and operational efficiency. The main advantages of Structural Machinery Solutions will be discussed in this article, along with the reasons why they are increasingly essential to contemporary buildings.

Benefits of Structural Machinery Solutions

1. Increased Speed and Efficiency in Building Projects

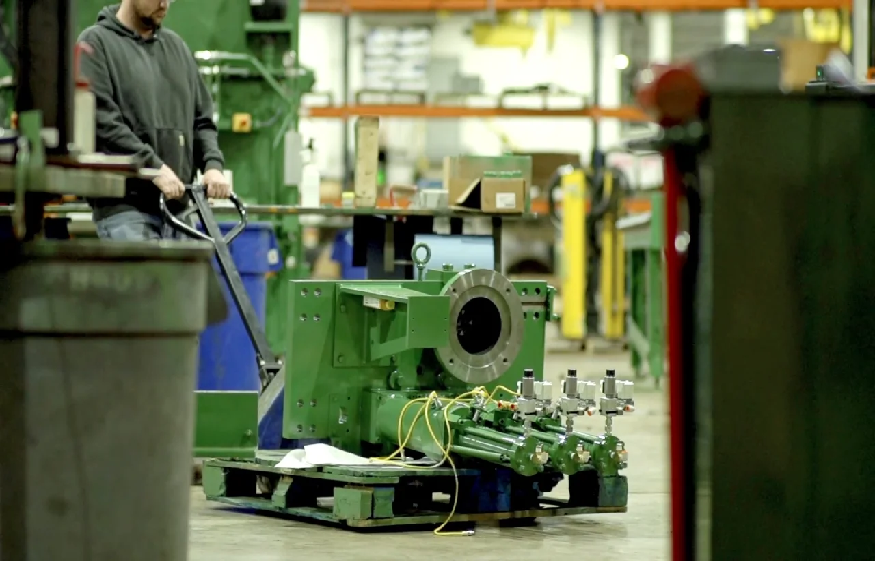

The increase in speed and efficiency during building projects is one of the main advantages of structural machinery solutions. When using structural machinery like cranes, bulldozers, excavators, and hoists, operations may be finished much more quickly than with human labour or antiquated equipment. Heavy lifting, moving dirt, and putting in structural elements are all completed in a fraction of the time. Reductions in the number of hours utilized to undertake those duties will save construction projects much time to end, thereby giving an opportunity for quicker handovers of a project and working on other construction projects. Solutions in structural equipment are a capital investment since there is a significant need for being efficient to fulfil rigorous timelines and minimize the costs that occur during any project.

2. Improved precision and accuracy

Structural equipment solutions offer a degree of accuracy and precision that is unmatched by human labour alone. The employment of modern technology in contemporary equipment ensures accurate measurements, perfectly positioned components, and precise building jobs. For example, the use of automated systems in cranes, bulldozers, and other equipment allows for precise control during operations. The risk of errors that otherwise might cause delay, rework, or extra costs is minimized through this precision. Precision in structural equipment solutions ensures that the foundation and the structure of a building are erected according to specific measures, thereby leading to higher-quality outputs in infrastructure development and construction sectors, which heavily rely on structural strength.

3. Higher Safety of the Operator and Workers

Safety first always prevails in any industrial or construction scenario. Given that structural equipment is manufactured taking safety into account, the chance of accidents and injuries when employees attempt to accomplish jobs that entail hazardous manoeuvring or heavy lifting is much reduced. For example, in order to reduce accidents, cranes, scaffolds, and hydraulic lifts are all fitted with state-of-the-art safety devices, including load stabilisation systems, overload sensors, and automated brakes. In addition, there is better ergonomic support for machines to help machine workers lessen the physical impacts associated with hands-on work. When machines are being used, fewer personnel are engaged in high-risk manoeuvres such as carrying heavy loads or working at altitude, which all lead to even safer working circumstances.

4. Longer Project Lifecycle and Durability

Structural equipment solutions are manufactured to last. They are built from tough, high-grade materials that are designed to last the harsh conditions that are commonly observed on construction sites. Since the technology allows one to deliver high-quality work focused on lifespan and structural integrity, this durability is also extended to the projects themselves. Using heavy-duty machinery, buildings, and structures are built to last for decades with minimal need for frequent replacement or repair. Using robust equipment minimizes downtime resulting from equipment failure, ensuring that projects are completed without unexpected delays. The lifespan of structural machinery affects both the projects in which it is used and the machinery’s durability.

5. Cumulative Cost Savings

Long-term cost savings are significant, although the initial investment in structural equipment solutions may be high. The demand for more workers or longer project schedules is reduced when jobs can be completed faster and more efficiently. In addition, compared to old or inefficient equipment, the maintenance cost is often lower due to the machinery’s reliability and durability. Higher precision of modern machinery also assists in avoiding expensive errors that can lead to rework, delay in the projects, and higher prices of materials. This provides for a lower cost for the whole total building project due to increased efficiency and quality, eventually having some cost-effective savings.

6. Greater Variety and Flexibility

Structural equipment is extremely versatile today. Its application extends through various phases of construction and use in buildings, ranging from the early excavations for foundation work on a project right up to fine finishes. Varying amounts of work could then be accomplished through adaptable equipment. Because of this versatility, with a minimum amount of additional equipment needed, cranes can be utilized to lift huge parts, excavators can dig foundations, bulldozers level the ground, and loaders can move supplies. In this manner, with such flexibility, construction teams will easily adjust according to the changing requirements of a project, be it in regard to the use of equipment that is readily adaptable for doing different construction works or another set of tools for a new duty. Machines that can be quickly adapted to perform a range of activities enhance resource utilization and project flexibility, reducing delays and increasing overall productivity.

7. Environmental Sustainability

The ability of structural equipment solutions to aid environmental sustainability is another important benefit. With technology advancement, many modern machines are designed with minimal environmental impact and energy efficiency in mind. More modern equipment is more energy-efficient, consumes less fuel, and emits fewer greenhouse gases. Structural machinery solutions help construction companies meet environmental standards and sustainability goals by reducing waste and using less fuel. Resource efficiency enables companies to become more respected as responsible, environmentally conscious companies while also aiding the environment.

Conclusion

Construction projects are being completed in a completely different manner due to structural machinery solutions in industrial equipment company in saudi arabia. These solutions have proven to be essential to the modern construction industry, increasing productivity, precision, safety, and durability. They help save long-term costs by providing quicker project completion, improved execution accuracy, and increased worker safety. Modern machinery’s environmental sustainability and adaptability also provide further advantages, allowing businesses to lessen their environmental impact while more easily adjusting to the demands of various projects. In the future, it will be very important to integrate the latest structural equipment solutions into the construction sector in order to ensure timely, cost-effective, and high-quality project delivery.